Sizing mud agitators for practical job site during well drilling

Mud agitator information

It’s typical assistant equipment in the whole well drilling mud system. We call it assistant or auxiliary equipment since we use a shaker, mud cleaner and other separation equipment as the 4 phases solids control system process.

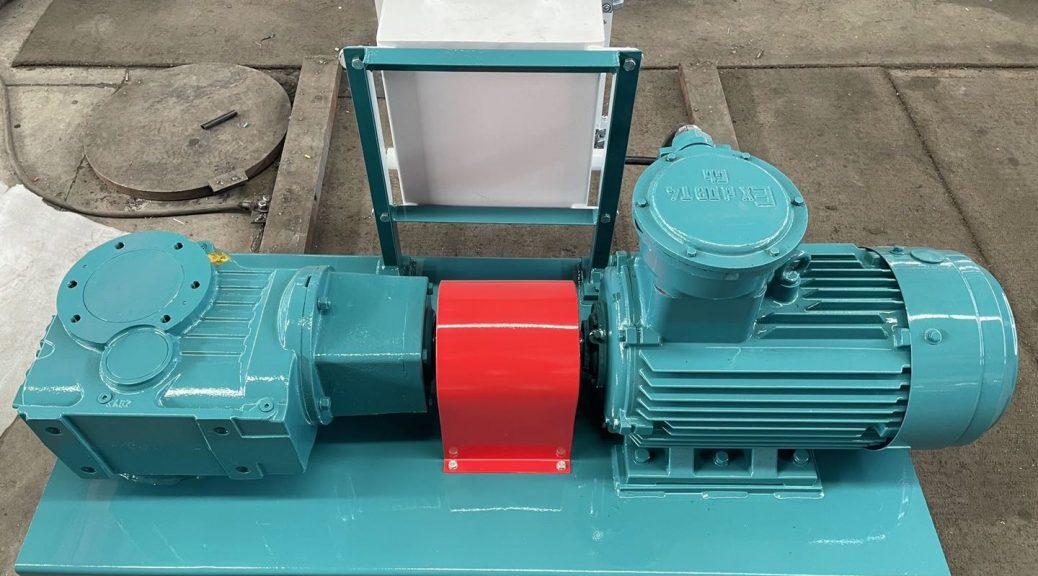

We call mud agitator mud mixers, too. Combining motor and gearbox directly or by coupling the agitator assembly will rotate according to our requirements. How to get the right configuration for the practical working condition? Talk about it later. But, actually, we have talked about this before.

Agitators in drilling mud solids control are usually right angle installation way. Such design is more reliable and stable than vertical installation, which means the motor output shaft and gearbox input shaft are perpendicular to the ground. For the mixers, we have many different designs on connection or combination. Such as connect the motor and gearbox directly or by coupling. Furthermore, we can set the motor and gearbox on a common pedestal or without a pedestal. We also can set a control panel or starter together with agitator assembly or not.

If we select the agitator properly we’ll get a better mud property and less cost for the mud process. How to select mud agitators then? How to size them?

Factors may affect sizing mud agitators

There are many factors that affect sizing agitator. Including but not limited to fluid or mud property, the volume of the tank, expecting TOR etc. What is TOR? It’s turnover rate and the unit is second.

Let’s find more details below

A compartment is 30 feet long, 10 feet wide, and 10 feet high. Maximum mud weight is anticipated to be 16 lb/gal (1.92 SG). If the maximum mud weight is not known, use 20 lb/gal fluid density(2.4 SG). All compartments will be solids-removal sections. Convert the compartment to symmetrical shapes. In this case, three compartments 10×10 feet square (3 x 3 m). Determine the volume for one compartment (Vt)

Vt = 10 x 10 x (10 – 1) x 7.48

= 900 x 7.48

= 6732 gal

Since the tank is deeper than 6 feet, we can’t use flat (turbine) impellers; therefore, we choose canted impellers. Appropriate impeller diameter from the impeller displacement table D so that TOR is within the recommended range. As a rule, choose an initial impeller displacement value so that D is close to Vt to increase the accuracy of the selection. We have shared the recommendation table on displacement D values. If the electrical input system is 60Hz we calculate the TOR as below for this example.

TOR = [Vt / D] x 60

= 6732/6343 x 60

= 1.06 x 60, or about 64 seconds

Please compare this TOR to values in the below table and determine suitability for compartment purpose.

The TOR decides the power of agitator

In this example, the TOR is sufficient for solids-removal compartments. If a lower numeric value to cause faster fluid movement is desired, then choose a larger impeller. If less movement is desired, choose a smaller impeller and recalculate until the appropriate values from the typical turnover rate value we have shared are achieved.

After determining which impeller will produce the effective TOR, locate the size in the Impeller Diameter columns in the below table. In this case, we anticipate using a 38-inch impeller and 16-ppg fluid. Since there is no 38-inch value in the 16-ppg column in the below table, we must round up to the next highest value, that is, 40 inches. This allows for a safety factor should the mud density increase slightly. Follow the 40- inch impeller value horizontally to the left in the table and determine the horsepower needed for that application. In this case, a 10-hp motor is sufficient. Therefore, three 10-hp agitators with 38-inch canted impellers are suitable for the tank in this application.

It should be noted that this system is for one brand of agitator, and the values in the tables may not apply to all brands. Deep tank designs require that multiple blades be mounted on a single shaft. This involves more thorough calculations than those shown. Because of this, it is highly recommended that the manufacturer or supplier be consulted before final design or placing of an order for any application

| Power Requirements for Canted Impellers per Fluid Density | |||||||||

| Impeller Diameter | |||||||||

| Power | 20 ppg | 16 ppg | 12 ppg | 8.3 ppg | |||||

| (2.40 SG) | (1.92 SG) | (1.44 SG) | (1.00 SG) | ||||||

| hp | kW | in | cm | in | cm | in | cm | in | cm |

| 1 | 0.7 | 22 | 56 | 24 | 61 | 26 | 66 | 29 | 74 |

| 2 | 1.5 | 26 | 66 | 28 | 71 | 30 | 76 | 32 | 81 |

| 3 | 2.2 | 29 | 74 | 31 | 77 | 33 | 83 | 34 | 86 |

| 5 | 3.7/4 | 32 | 81 | 34 | 86 | 36 | 91 | 38 | 97 |

| 7.5 | 5.6/5.5 | 35 | 89 | 37 | 94 | 39 | 100 | 42 | 107 |

| 10 | 7.5 | 37 | 94 | 40 | 102 | 43 | 109 | 46 | 117 |

| 15 | 11.2/11 | 42 | 107 | 45 | 114 | 49 | 123 | 51 | 130 |

| 20 | 14.9/15 | 46 | 117 | 50 | 126 | ||||

| 25 | 18.6/18.5 | 49 | 124 | ||||||

| 30 | 22 | ||||||||

Special situations for agitator selection

Besides solids control application, there are agitators for other uses. Such as waste management or sludge treatment. As well as the mud recycling or fluids compounding and pill mixing.

For different industries or uses, we’ll design various agitator to cater for optimal performance. So, if you do have requirements for agitators, not only mud agitator please feel free to contact us. We wish our suggestion will do you favor and help you on certain projects. It can work for oilfield project, chemical project, food and pharmacy, etc.

Ye, for some use and industries, the above information may not work. So please don’t hesitate to let us know your detailed requirements and give us sufficient information to propose ideal solutions for you.

Anyhow, necessary information for sizing agitators including the material you need to process, the property or features, how do you like the agitator to perform. Such as installation position, speed or TOR, even power limit, or other requirements. Why suggest selecting AIPU as your partner, every year we deliver about 300 sets of agitators all over the world. They are not only working for the oil and gas industry but also other applications. Leave comments below or call us now!

One thought on “Sizing mud agitators for practical job site during well drilling”