High quality manufacturer’s desilter

The mud remover is the third level solid control equipment in the drilling system, mainly used to remove solid particles ranging from 15 to 44 microns, and is an important equipment in the solid control system..

Working principle

The drilling mud is transported to the desander cyclone through a sand pump located in the desander compartment. Under the pressure of the sand pump and the impact of the mud flow, the drilling mud forms a vortex within the cyclone. Meanwhile, the solid in the drilling fluid settle at the bottom of the cyclone due to the combined forces of centrifugal force and gravity. Eventually, these solids are expelled through the drip nozzle. Solid particles will be further screened and filtered using the underflow sieve. The lighter and cleaner liquid will flow directly into the desilting bin through the discharge pipeline of the cyclone group. The liquid in the mud removal bin will be further supplied to the centrifuge for the fourth stage of solid control treatment, using the centrifuge pump.

Scope of application

Secondary solid control treatment of mud and liquid to be treated in land and offshore oil and gas drilling, coalbed methane excavation, non-excavation directional crossing, pile driving engineering, waste sewage treatment, and mud treatment. In short, it is suitable for removing mud and solid-liquid mixtures in various environments. The particle size generally excluded is >14 microns.

Structural components

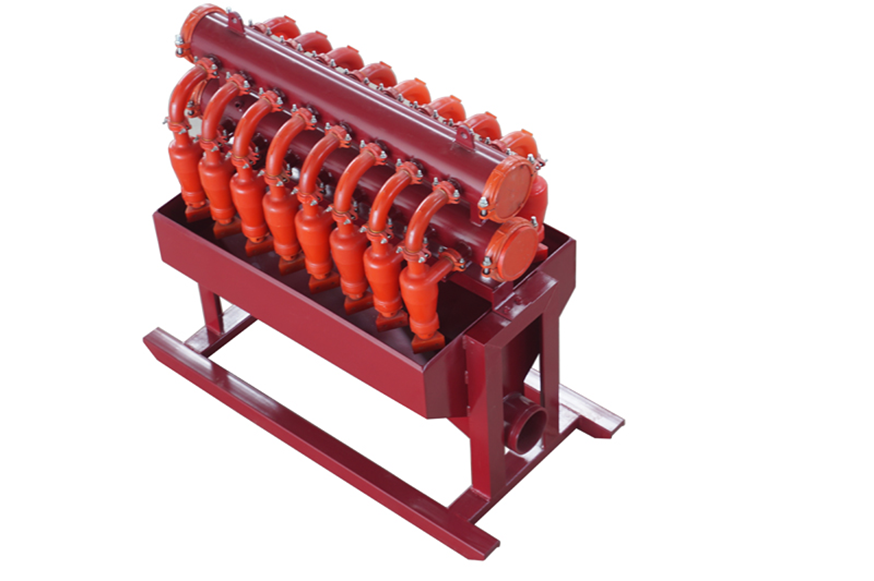

Structural components: mainly include the base, frame, excitation motor, control cabinet, cyclone group, corresponding pipelines, screen, and fixed screen device. Some customers may request that the Desilter does not have a bottom flow screen and only requires a quicksand trough. In this way, the structural components do not include the excitation motor, control cabinet screen, or fixed screen device.

Equipment features and advantages

- The desilting cyclone adopts high wear-resistant polyurethane material, which has a longer service life.

- Simple connection method for easy disassembly

- The underflow screen can be replaced according to requirements

- Easy to operate with minimal loss and easy to maintain

- Strict sanding and spraying procedures.

- Customizable project parameters

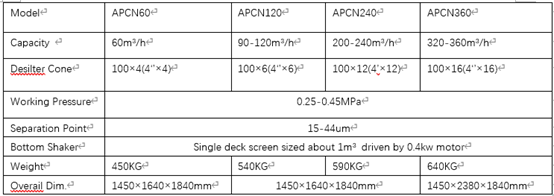

Detailed parameters