Differences and applications of degassers

What is a degasser?

The degasser is the important equipment used in a solid control system. The main function is to separate particles and harmful substances from the drilling fluid mud. By removing bubbles from the drilling fluid, the degasser also helps to reduce the risk of explosions and other hazards at the drilling site. The degasser is an efficient device for removing bubbles from the drilling fluid mud, which is a specialized equipment suitable for drilling fluid mud.

The centrifugal degasser advantages

- Small footprint

- High degassing rate

- High processing power

- No need to equip with a slurry pump

- Easy to operate and maintain

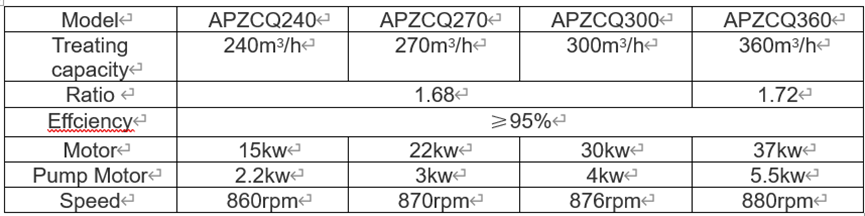

Model dimensions

Vacuum degasser

Vacuum degasser is the second stage purification equipment in the drilling fluid mud system, mainly used to remove invading gases, remove small bubbles wrapped in liquid film, break and efficiently separate harmful invading gases such as hydrogen sulfide and methane in the drilling fluid, and fully stir the drilling fluid.

Equipment characteristics and advantages of vacuum degassers

- No need to equip with a slurry pump

- High degassing rate

- Compact and portable design

- Spray wear-resistant and corrosion-resistant materials.

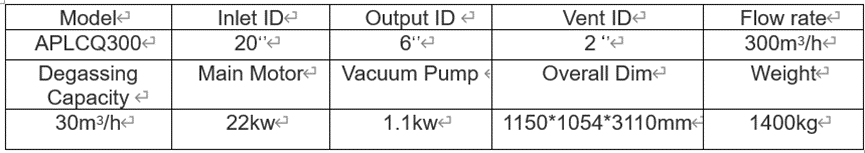

Model and size