What is drilling mud shear pump?

Drilling mud shear pump brief

Drilling mud Shear pump is a new type solids control equipment. It can configure and process drilling mud quickly, satisfy demand of high property drilling fluid. Shear pump can mix and hydrate drilling fluid effectively. And the material added in drilling mud is saved to save cost. It also saves configuration time and providing high performance mud for drilling process.

Drilling mud shear pump function

- Shear pump can hydrate bentonite much better and provide higher performance of drilling mud.

Bentonite particles dispersion and hydration degree depends on many issues. Including electrolyte content in water, time, temperature, quantity and concentration of the replaceable cation. On the same conditions, the drilling fluid shear pump can save bentonite particles over 30%.

- Drilling fluid shear pump can shear and hydrate polymer in time.

Since polymer used in drilling mud molecular level is rather high and it’s difficult to hydrate if we add polymers directly, therefore, polymers need to be cut down in advance. Shear pump can provide high shearing efficiency, polymer dilution, hydration process.

Structure and working principle of shear pump

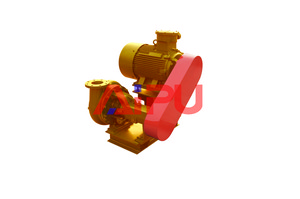

Drilling mud shear pump is composed of an impeller, volute, support, drive shaft, pulley, combination belt, motor and bearing.

Drilling mud shear pump impeller is different from general impeller and structure is more complex. The impeller is the hardcore component of shear pump, high cutting efficiency. The impeller is mainly composed of five parts, including Axial flow turbine, storage tank, pump wheel, a pressurized cabin and shear plate. Its Structure is compact so can help to shear material effectively.

Axial flow turbine provide fluid with a certain capacity to pump wheel and storage tank. 50% of the fluid through the pump wheel get into volute casing. And the other 50% absorbed by storage tank injected through the nozzle perpendicular to the shear plate. After fluid injected transferred by pump wheel mixed. The speed of shear plate serration is very high. So materials are cut again by high speed serration. Therefore, the drilling mud will be sheared through the impeller repeatedly. Under the shearing pump operation we can then get better fluids. Finally, clients select such pump for the special demand