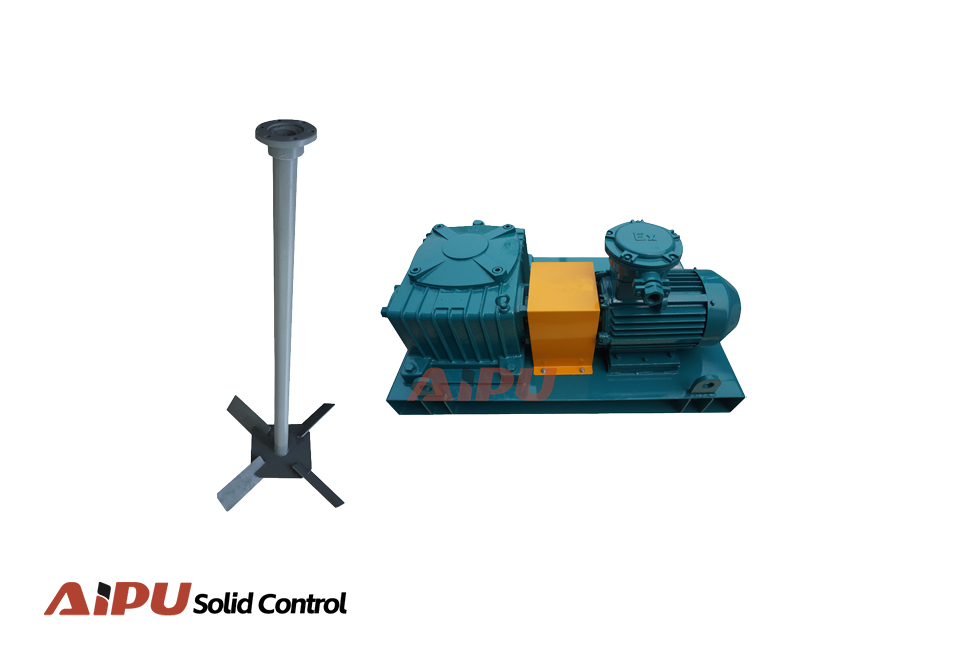

Image Description

The Vacuum Degasser is a critical second-stage system component designed to efficiently remove entrained and potentially hazardous gases—such as hydrogen sulfide, methane, and carbon monoxide—from the drilling fluid. Operating on a vacuum principle, it breaks down and extracts fine gas bubbles trapped in the mud, ensuring fluid stability and preventing operational risks like reduced pump efficiency or well control issues. Key features include a self-priming design that eliminates the need for an additional feed pump, high degassing efficiency exceeding 95%, a compact and robust construction with wear- and corrosion-resistant coatings, and the availability of international safety certifications (ATEX, IEC, UL, DGMS). It offers flexible configuration options, including customized electrical systems and material choices like H2S-resistant steel.