Desander Gallery

Browse our complete collection of Desander equipment images. Find detailed product photos, specifications, and technical information for all our Desander models.

Premium Desander Series

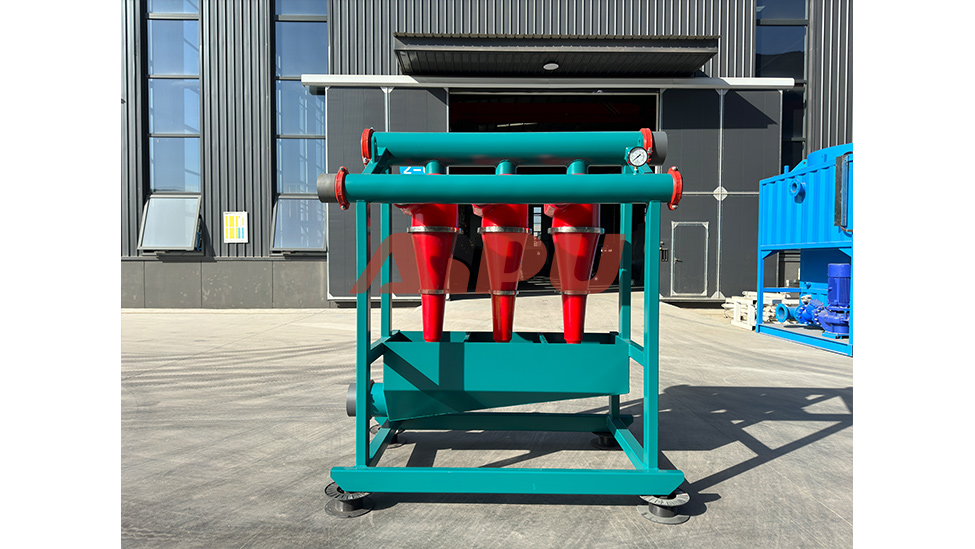

The AIPU APCS Desander serves as a critical secondary-phase solids control equipment, efficiently removing abrasive particles between 44-74μm from drilling fluid. Utilizing high-efficiency polyurethane cones with cast-iron reinforcement and clamp-type connections, it ensures easy maintenance and reliable performance. This unit effectively protects downstream equipment from wear, maintains optimal drilling fluid properties, and reduces overall operational costs. Optional bottom shaker attachments and international certifications (ATEX/IEC/UL) make it adaptable for global drilling operations in both solids control systems and waste management processes.

Desander

The APCSseries desander helps stabilize your entire process by providing consistent, reliable solids removal from the start.

Desander

The APCSseries desander utilizes centrifugal force to swiftly and effectively separate solids from liquid streams.

Desander

Implementing the APCSseries desander is a proactive step towards minimizing unplanned downtime and maximizing profitability.

Desander

The robust construction of the APCSseries desander guarantees long-term, reliable performance in harsh operating conditions.

Desander

By maintaining clean process fluids, the APCSseries desander directly contributes to improved end-product quality and consistency.

Desander

The APCSseries desander features a user-friendly design for easy operation, maintenance, and parts replacement.

Desander

Specifically engineered for the oil and gas industry, the APCSseries desander tackles the toughest sand removal challenges.

Desander

With its high-capacity design, the APCSseries desander handles large fluid volumes without compromising separation efficiency.

Desander

The APCSseries desander offers a cost-effective solution for extending the service life of valuable downstream components.

Desander

Trust the APCSseries desander for unparalleled protection against abrasive wear in your fluid handling systems.

Desander

Maximize your operational uptime and productivity with the dependable solids-removal performance of the APCSseries desander.

Desander

The APCSseries desander provides a critical first stage of solids removal, extending the life of your entire fluid system.

Desander

Integrating an APCSseries desander into your system safeguards pumps and pipelines from sand-induced damage.

Desander

The compact and durable design of the APCSseries desander makes it ideal for both onshore and offshore applications.

Desander

Utilizing high-efficiency hydrocyclones, the APCSseries desander delivers superior solids control in demanding environments.

Desander

Engineered for reliability, the APCSseries desander is a key component for maintaining optimal fluid properties.

Desander

The APCSseries desander ensures cleaner fluid processing, enhancing the overall efficiency of your operation.

Desander

By efficiently removing abrasive particles, the APCSseries desander significantly reduces maintenance costs and equipment wear.

Desander

Designed for robust performance, the APCSseries desander protects downstream equipment from abrasive solids.

Desander

The APCSseries desander effectively separates and removes sand and solid particles from drilling fluids.

Desander

The APCSseries desander efficiently removes abrasive sand and solids to protect downstream equipment and enhance operational efficiency.

Desander Technical Specifications

| Model | Max. Capacity | Cones Number | Working Pressure | Separation Point | Bottom Shaker | Power | Screen Size | Screen Area |

|---|---|---|---|---|---|---|---|---|

| APCS60 | 60m³/h | 200×2(8"×2) | 0.25~0.45MPa | 44~74μm | Single deck, 1㎡, 0.4kW motor | - | - | - |

| APCS120 | 90~120m³/h | 250×1(10"×1) | 0.25~0.45MPa | 44~74μm | Single deck, 1㎡, 0.4kW motor | - | - | - |

| APCS240 | 200~240m³/h | 250×2(10"×2) | 0.25~0.45MPa | 44~74μm | Single deck, 1㎡, 0.4kW motor | - | - | - |

| APCS360 | 320~360m³/h | 250×3(10"×3) | 0.25~0.45MPa | 44~74μm | Single deck, 1㎡, 0.4kW motor | - | - | - |

| Hunter S120 | 120m³/h | DN250×1 (10"×1) | 0.25~0.45MPa | 44~74μm | Included | 2×1.5kW | 1165×585×40mm (120mesh)×3 | 2㎡ |

| Hunter S240 | 240m³/h | DN250×2 (10"×2) | 0.25~0.45MPa | 44~74μm | Included | 2×1.5kW | 1165×585×40mm (120mesh)×3 | 2㎡ |

| Hunter S360 | 360m³/h | DN250×3 (10"×3) | 0.25~0.45MPa | 44~74μm | Included | 2×1.72kW | 1165×585×40mm (120mesh)×4 | 2.7㎡ |

| Hunter Ms120 | 120m³/h | DN250×1 (10"×1) | 0.25~0.45MPa | 44~74μm | Included | 2×0.75kW | 750×900×27mm (100mesh)×2 | 1.35㎡ |