Shaker screens area calculation and effect to shale shakers

Shaker screens area means the general area of the screen panel. If we calculate the screen area of 1 set shaker, we need to consider each piece of screen size or dimension first. Then multiple numbers by area of each panel.

Example of shaker screens area calculation

To explain this clearly, please find the following example. We take the Hunter-D4 shaker as an example. This model of shaker holds 4 panels of the screen in total. Each piece of screen is about 27.5in x 41.3in. That means the area of each screen is about 1136 sq. in. Finally, the general or gross area of the screen on the whole shaker is about 4544 sq. in.

How about the whole screen area for all shakers in one mud system? That requests multiple screen areas of the whole shaker set by the shaker quantity. Furthermore, some clients will calculate the mud cleaner screen area, too.

But some clients pay more attention to the effective screen area. That means, what is the percentage of screen area to process or filter the drilling fluids. This is defined by the screen non-blanked area itself. While, how to know the non-blanked area of the whole panel?

The effective screen area information

Firstly, we need to deduct the blanked edge of the screen panel. Such as frame screens, there are tubes on each side of the frame; while hook strap screens hold blanked areas, too. Furthermore, the grids of each screen are not effective filtration areas neither.

But, if we just calculate the area in such a way it will take a long time and much energy. So we can use the specific units and calculate a certain piece of the screen then derive the effective surface of the whole screen.

How to do such work? We know there is API RP13C telling the guidance and details to test non-blanked areas. Let’s find the summary as follows. We take the open hook strap screen as an example.

Measure the length and width of a panel opening with a dial or digital calliper to the nearest millimetre and calculate its area. If, for example, it measures 24 mm wide by 25 mm long, its area is as follows: 24 mm × 25 mm = 600 mm2

Perform a similar calculation for all panel openings on both screens used in the analysis. Sum the individual results to obtain the total non-blanked area of each panel-mount screen, in square millimetres. In one set of calculations, the resultants sums are: 626 400 mm2 and 618 734 mm2, or 0,626 m2 and 0,618 m2

If necessary, convert the total non-blanked area to square feet by using the conversion factor.

626400mm2 /92903=6,74ft2; 618734mm2 /92903=6,66ft2

Average the two non-blanked area results to obtain the final answer for a total non-blanked area of a

panel.

[(0,626 m2) + (0,618 m2)]/2 = 0,622 m2 If using square feet: [(6,74 ft2) + (6,66 ft2)]/2 = 6,70 ft2

NOTE The total non-blanked area for an open-hook strip screen panel is calculated as follows.

a) Measure the width of each screen panel from the inner edge of the hook strips on either side.

b) Measure the length of the non-blanked area of each screen panel, starting from the inside edge of the top cloth fold and extending to the inside edge of the bottom cloth fold.

c) Calculate the total non-blanked area, in square millimetres, of each screen panel:

⎯ screen panel #1: 1160mm×1520mm=1763200mm2=1,763m2

⎯ screen panel #2: 1156mm×1522mm=1759432mm2=1,759m2

If necessary, convert the total non-blanked area of each screen panel from square millimetres to square feet by performing the following calculation:

⎯ screen panel #1: 1 763 200 mm2 / 92 903 = 18,98 ft2

⎯ screen panel #2: 1 759 432 mm2 / 92 903 = 18,94 ft2

d) Average the two non-blanked panel area results to obtain the final answer for the total non-blanked area of one open hook strip panel: (1,763 m2 + 1,759 m2) / 2 = 1,761 m2

If necessary, calculate the average in square feet: (18,98 ft2 + 18,94 ft2) / 2 = 18,96 ft2

Why screen area affects?

Shale shaker filter the cuttings by screen panel. The contact area is the volume or capacity of the shaker to some degree. While the larger the effective area, the sooner fluids pass through the medium. So, finally, we’ll get the more efficient equipment.

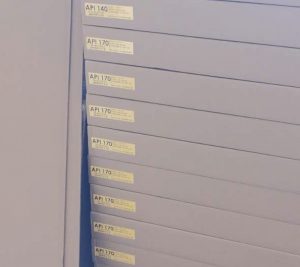

That is why clients request suppliers to mark the non-blanked area on-screen tag. Also, that’s why users prefer the API RP13C conformed screen. This will help users to get optimal screen panels easily.

Please contact Aipu Solids Control to get more information about our API RP13C screen. There is a complete report from the reputed organization.