Screw pump brief introduction

Screw pump is a kind of rotary pump. Its transferring liquid or increasing pressure relays on space change between pump body and screw bar. According to screw bar quantity screw pumps including single screw pumps, dual screw pumps and triplex screw pump. When positive bar rotate will force the negative bar rotate together then the screw engagement space at suction end will be increased and pressure will be smaller.

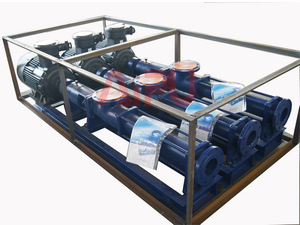

Aipu screw pump structure

One set of screw pump is composed with pump, mounted on the lower end of the rubber bushing and the pump rotor and the driving shaft connected to the screw pump motor, upper end portion of the structure connected with the pump mounting frame. Driving motor mounted on the connecting frame.

Screw pumps working principle

The single-screw pump, a type of rotary positive-displacement pump with internal gearing. The main components including a stator with dual spiral chambers and a rotor engaged with the stator in the shaft bushing.

When the rotor is making planet turning movement by circling the axial line of the stator in the stator chamber, the sealed chamber formed between the rotor and stator will make axial displacement along the spiral line of the rotor, which will convey the liquid evenly, continuously and constantly from the suction to the discharge side.

Screw pump application

We operate screw pumps widely in oil and gas drilling section, environmental production, shipbuilding industry, medicine, brewing industry, construction industry, mining industry, chemical industry, printing and paper industry. According to the size of pumps can transport different from 0-200000 centipoise viscosity of the medium.

The advantages of Aipu screw pumps

- Low pulsation for smooth, quiet operation.

- Direct-drive and easy to operation.

- Low shear for protection of the pumped fluid.

- Hydraulic balance for minimal deflection and wearing.

- Cartridge-type rotating assembly for easy servicing.

- Integral relief valve to eliminate external valves and piping.

- Built-in heat jacket to facilitate cold start.

- Customized ports to adapt best piping arrangements for the system.

- Selecting materials for the longest service life.