Pumps for drilling mud processing system at drilling site

Pumps for drilling mud process including many different types. Please find below details for your reference.

Drilling mud system information

A mud system is a complete unit to process drilling fluids during well drilling. No matter oil drilling, gas drilling or geothermal well drilling.

Drilling fluids help to grease drilling bits and pipes, helps to cool down the drilling bit, also help to bring the cuttings or solids out of the wellbore and help to strengthen the bore wall. So we use such liquid during well drilling. To get better performance and higher effectiveness, we’ll process the drilling mud and reuse them; we’ll remove the harmful material and recycle the useful material as a closed-loop circulation.

In a complete mud system, there are main mud equipment and auxiliary equipment. The pumps we talk about here are the auxiliary equipment. However, they are important to mud circulation. Let’s find the following information in detail

Pumps for drilling mud processing

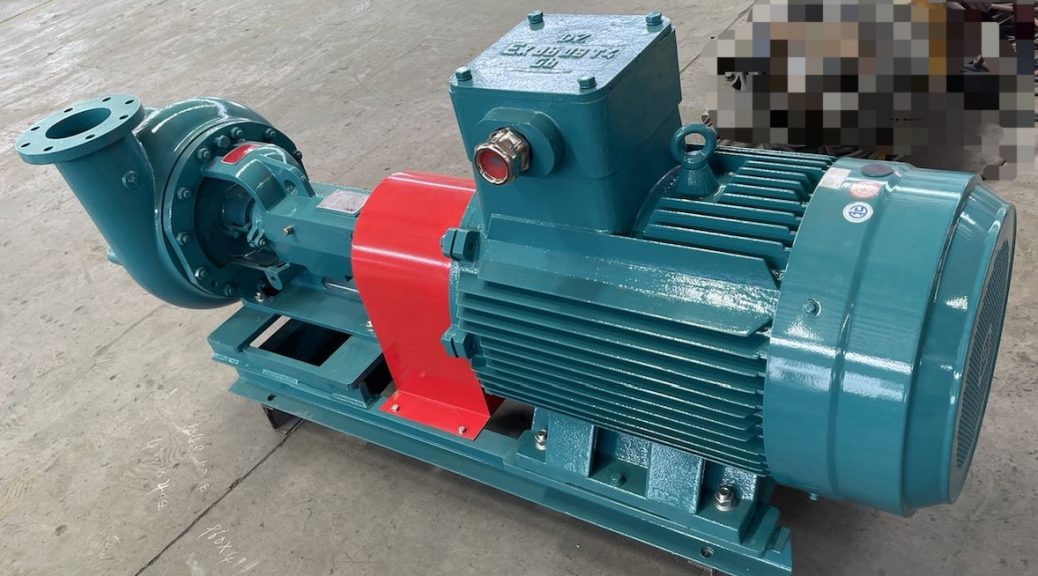

For oilfield drilling mud processing, as per function, pumps usually including the trip pump, desander pump, desilter pump, centrifuge pump, mixing pump, shearing pump, water pump, and charging pump.

These pumps are almost horizontal designs and we call them centrifugal pumps. For the centrifuge pump, we can use either a submersible slurry pump or the screw pump. Desander pump and desilter pump will feed drilling mud from tank to cones, under sufficient pressure from the pump the flow will become a swirl. Then the solids with a heavier gravity will be separated out of fluids under the centrifugal force.

Regards the mixing pump, it’s a combination of pump and hopper. Still its principle is centrifugal force and pressure. There is a Tee connector with educator and valve. We connect pump output, funnel inlet and discharge line, finally we compound the mud material and liquid completely.

The shearing pump is usually overhead design with pulley and belt. Its working principle is same with other common horizontal pump, however, the difference is impeller of the pump. Under the dual function from rotation of impeller and the flow, it helps us to get the even fluids without lumps of polymer.

For the trip pump and charging pump, they work when it’s necessary for mud pump. Water pump can be used to transfer water for mud system or for cleaning tanks.

How to place pumps?

Pumps position depending on general design of whole system. Such as tanks layout, function area division, etc. But usually we suggest placing pumps for drilling mud processing as below.

Desander pump and desilter pump are usually fit on the shaker tank or the processing tank. We can mount them at one end of the shaker tank close to mud cleaner, also can mount them at the side of the sand trap pit. There will be a slanted wall and provide space for feeding pumps. When we configure mud cleaner on another tank different from the shale shaker tank, the pumps are on the mud cleaner tank. Either end is ok for the 2 pumps. We suggest setting them close to mud cleaner or hydrocyclones, which requests fewer pipelines. We fit trip pump on shaker tank, too.

And for the decanter centrifuge pump, if we use a submersible slurry pump we’ll set it beside the centrifuge or over the desilter tank. It pumps clean fluid after desilting to centrifuge. If we use a screw pump, it’s a horizontal type, we’ll mount it below the compartment on desilter tank or centrifuge. The flow process is same as the slurry pump.

The mixing pumps are usually fit on the mud mixing tank one end. There are different designs, too. Such as a dual mixing pump, which means the two pumps and two hoppers are on the common skid or base. Another design is a single mixing pump. We also can design it as a separate hopper and pump. Such as hopper on the tank top, while the pump is below the tank top or grid cover. Some clients may request a separated skid with mixing pump(s).

Maintain the drilling mud process pump

Centrifugal pumps we use for drilling fluids system are mature products for decades. Since the design of mechanical seal utilization, the pumps are very easy to maintain. We also have talked about this topic many times before.

A very important tip is “DO NOT RUN THE PUMP WITHOUT MATERIAL”. Others suggestions below for your reference, too.

Firstly, please operate pumps according to instruction. Considering the flow rate, power, mud density, etc.

Secondly, maintain pumps regularly as per operation and maintenance rules. Such as, check the couplings, and check if any leakage, etc.

Finally, before repairing the pump and replacing parts ask professional or trained people to do necessary inspection; or inquiring suppliers for special solutions.

During the replacement of wearing parts, please pay attention to all wearing parts. Even there is no damage we can check if any potential worn and do the necessary replace in time.

Every shut off of pump request a complete cleaning. Such as drainage port, the internal case, impeller attachment, etc.

Kindly check above suggestions for your reference. If you have different opinion or other questions just contact us freely. Trust you’ll get the optimal solutions here. Not only for pumps but also for all mud processing proposal.