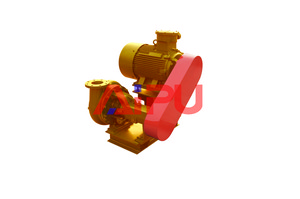

High quality shear pump from Aipu solids control

Shear pump is a new type of pump and offer fast treatment for the drilling mud. The shear pump can mix and hydrate completely and effectively the material added in the drilling fluid, save the mud material , reduce the time of configuration, and provide the high performance mud for the well drilling.

Shear pump working principle is based on centrifugal theory, through the improvement to develop a new, efficient centrifugal pump, it is designed for quick preparation and dispose drilling fluid in the solids control equipment system.

Working principle of shear pump

The turbine axial flow provide the certain displacement flow for pump impeller and storage tank, the 50% of the liquid discharged through the pump impeller and enter into the volute casing. The other 50% liquid is absorbed by storage tank. The unique design of the pressure cabin make the liquid in storage tank have the certain energy. The liquid discharged through pump impeller parallel to the shear plate flow with the higher flow speed. The inspiratory liquid by storage tank through 44

nozzles perpendicular to the shear plate injection. The injection fluid mixed with the fluid discharged by pump impeller with the higher flow speed impact the shear pump saw tooth, the high speed rotary shear plate saw tooth re-sheared the fluid. So the fluid flow through the impeller will bearing many times shearing action.

The advantages of Aipu shear pump

Shear pumps are new type equipment of petroleum and gas for solid control in drilling. Considering the bad working environment of the shear pump, Aipu has special requirements for both manufacturing and purchasing pivotal accessories to extend the service life. Impeller and packing box are both manufactured by high quality stainless steel. Mechanical seal and importing oil seal.

- Aipu shear pump adopted comprehensive mechanical seal

- New and chicly designed lead equipment more durable for long service life

- Make the bentonite hydration easier also save bentonite over 30%

- Strong power for polymer hydration provide high property drilling mud

- Decrease mud plate and fluids lose

- High performance and competitive price.