Some tips for mud mixing pump

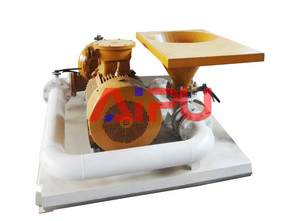

In drilling process, solids control equipments are necessary and indispensable. Jet mud mixing pump is one of them and it plays a very important role in drilling mud solids control process. Aipu solids control not only produce the single mud mixing pump, but also can make the double mud mixing pump. Double mud mixing pump is usually made of two sand pumps and two mud hoppers which are all installed a common base.

The main effects on mud mixing pump

The first is to try to decrease the hydraulic frictional losses of mixed funnel as far as possible, otherwise the treating capacity may be greatly reduced.

The second is that the distance from nozzle to venturi tube should be proper, and the best efficient distance is 32 to 90 mm. Generally speaking, it is not more than 90 mm, otherwise barite charging speed will be significantly reduced.

The third is that the back pressure of the outlet pipe should be moderate.

The notice for mud mixing pump

In order to make the jet mud mixer and used more effectively, the following parts should be noticed.

- Select the mixer suitable for drilling fluid system. In general, for most drilling equipment, a funnel is enough, and we always consider using a funnel of the capacity of 240m³/h.

- Keep the distance between pipeline and funnel as short and straight as possible.

- Use the new parts to reduce friction loss. Every time after working, use a clean liquid to rinse the entire system. Special attention should be paid to cleaning funnel inlets.

- Regular Maintenance and inspection should be done like other drilling equipment.

When we use mud mixing pump, above items should be noted as much as possible. If you have any questions for jet mud mixing or other solids control equipment, please feel free to contact us, we will definitely give you best solution to meet your any requirement.