Mud gas separator maintenance

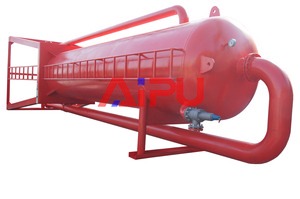

Mud gas separator is a special kind of equipment for primary degasification from gas-bearing drilling fluid in the process of drilling. Mud gas separator and flare ignitor are commonly used together as a complete gas disposing system.

Separating principle of mud gas separator

The gas-bearing drilling fluid from throttling manifold flows into decompression tank through incoming-stream manifold of separator, then enters the separating tank through output pipe. The gas-bearing drilling fluid dashes on a series of baffles, it makes the bubbles in drilling fluid break up. And when the drilling fluid flows through the surface of baffles, it becomes turbulence to enable the gas separate from it. The bubbles are kept on the surface of baffles and inflate and break up.

Mud gas separator maintenance and attentions

- Open the screw plug for sand discharge in the manifold side to remove sand when the mud discharge manifold is blocked.

- The separator assembly is pressure container, so it must be used in designed working pressure and surroundings. Overpressure work is forbidden. The safety valve should be checked at least once a year.

- The baffle should be checked after a well has been completed. Replace it if there is something wrong.

- Welding on the separator assembly is forbidden.

- The exhaust pipe and liquid discharge pipe should be arranged separately when the separator is paralleled. Uniting the pipes is forbidden.

Mud gas separator should meet the flowing requirement

- According to practical experience, choosing the treating capacity of mud gas separator should be 5 times of designing circulation.

- The diameter of inlet pipe of mud gas separator should be equal to or more than the diameter of the throttle pipe line

- The inner diameter of the discharge pipe of the liquid gas separator shall be no less than the inner diameter of the inlet line, drilling fluid directly discharged to the inlet pipe of shale shaker or mud tank.

- The diameter of the exhaust pipe should be 200mm (8in) or more.

- The valve don’t need to be installed on gas discharge pipe.

Aipu Machinery has won high recognition and praise from domestic and abroad with science core technique and a lot of innovative patents. At present, Aipu Machinery’s business scope has covered the whole world. Welcome to Aipu solids control inquiry.